As aforementioned about two types of solar panels (monocrystalline and polycrystalline) in one of our articles, we are yet to discuss one of the most renowned brands for making the solar modules and panels which is Jinko Solar. Having founded in 2006, Jinko Solar has ranked as one of the largest solar panel manufacturers in the world since 2016, nearly a decade after its inception. Jinko Solar is based in China, and it’s currently operating in 70 countries along with its manufacturing facilities in China, Malaysia, and the US. This standalone company’s unfaltering manufacturing quality and indomitable services to its customers have garnered it a huge reputation in countries like UK, USA, Australia, South Africa, Mexico, Germany, UAE, France, Belgium, China and many more.

The company embarked on a little experience of producing solar materials, such as silicon ingot with larger size between 2006 and 07 followed by it became a sole manufacturer of salamis and silicon wafers. From 2009, the company stepped into making the solar panels using their own unique wafers extracted from the ingots and then began to flourish since 2010 by generating cash flow while incorporating with the stock market. For the last four years since 2016, the company is thriving the solar industry with an annual production capacity of 17.5GW mono wafers, 10.6GW solar cells, and 16GW solar modules as of March 31, 2020. Consequently, Jinko Solar had shipped a total consignment of 14.3GW globally alone, thus making it one of the most formidable solar panel manufacturers.

Having employed 15,000 people, Jinko Solar is famous for serving tier 1 products all around the world. Australian solar company heavily relies upon the Jinko Solar products. As a result. Jinko has a head office located in Sydney along with its dedicated warehouses in Sydney, Melbourne, Brisbane, Adelaide, and Perth. Since the company is firmed at maintaining its logistic service worldwide and also acknowledges the Aussies’ obsession for the local services, it has devoted itself to help you expand your solar businesses in Australia by forming a group of dedicated teams. The local distributors ensure that their products get delivered on time, and the products will remain in their immaculate and pristine condition. Cyanergy takes pride in as one of the sole distributors of Jinko Solar panels. All the solar panels manufactured in Australia by Jinko are compatible against the salt mist corrosion.

JinkoSolar is a quintessential vertically integrated company that ensures thorough inspection of the manufacture of the unblemished quality solar panels to its processing, delivery, and auditing without imposing any pressure on other divisions of the company. The in-house quality-controlled standard accelerates the solar modules to pass through the TUV and IEC standard tests. Jinko Solar’s way of making the distinctive ingots and wafers, suitable for the solar modules and panels, assures that they meet the highest standards set by the company, which is also reinforced by the advanced ICP-MS and PL photoluminescence testing.

Our state-of-the-art manufacturing process is second to none as it is tested by the assigned third-party audit institutes, resulting in it provides premium quality solar modules to its customers. A joint venture between Jinko and DuPont allows the company to receive all the genuine raw materials, such as Tedlar back sheets and metallization pastes, in particular, to make their formidable pieces of solar modules.

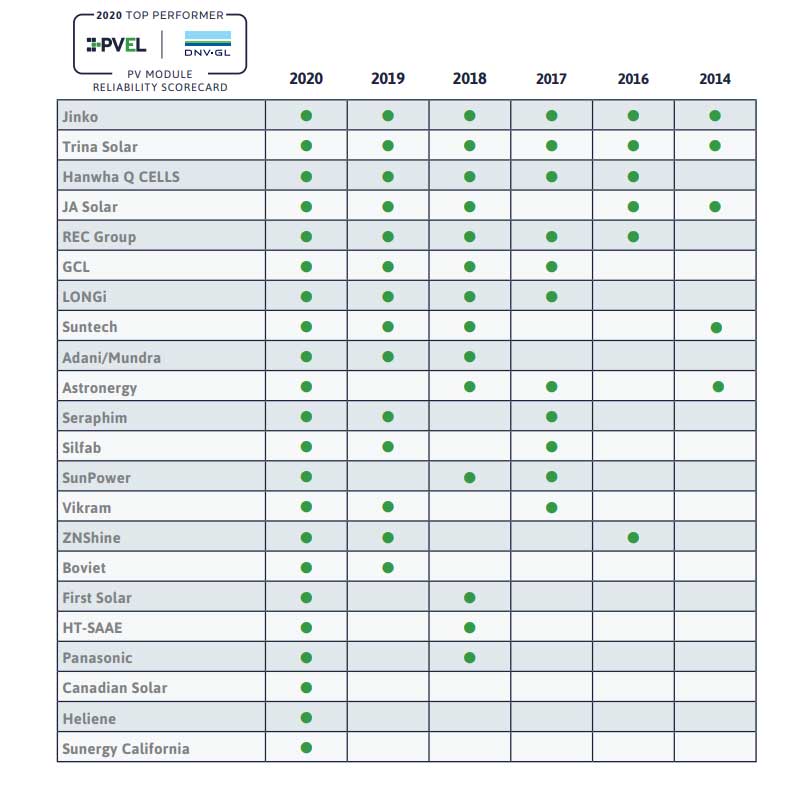

The mystery behind the success of the Jinko Solar underpins its emphasis on the R&D (Research and Development), quality control, performance measurement, and meticulous durability testing. Thus, Jinko Solar has been championed as the world’s largest solar manufacturer, by one of the most leading independent solar module inspection and performance services named, PVEL (PV Evolution Labs). They nominate those solar modules that possess less than 2% degradation based on thermal cycling, dynamic mechanical load, humidity freeze, and potential induced degradation (PID).

2020 PV Module Reliability Scorecard

From the table published by the PVEL, it is evident that the Jinko Solar has led the solar industry for the past 5 consecutive years leaving behind all other contemporary prominent companies. Most of the solar businessmen and professionals opt for their solar installations and procurement based on the review transcribed in the PVEL scorecards.

One of the most tangible differences between the top-notch and mediocre manufacturers is their allocation of budget in the R&D sector. An enormous research and a case-to-case experiment indicate the manufacturer’s commitment to bringing out more robust and invincible technology in the solar industry. Likewise, Jinko in the hope to be a leader in this competitive solar market proves that they want to shape the future of the most successful solar businesses in the world and hence in Australia.

Jinko Solar had never been at the forefront of patronising any innovation or advanced solar prototypes on their own. The company was only interested in the solar products that have already been experimented or used in a full swing by most of the manufacturers. Up until now, the company was manufacturing P-type PERC cells followed by P-type half-cut cells, before transitioning into the latest N-type half-cut cells as illustrated in the diagram above. However, the wait is over as the Jinko Solar has a new Tiger series in the pipeline which is completely a new form of solar panel distinguished from the basic no-frill solar panels.

Most of the panels come with either 60 cells or 72 cells, and Jinko Solar manufactures both kinds of panels whether it’s monocrystalline or polycrystalline solar panels. However, the recent half-cut technology has enabled Jinko to manufacture most of its 72 or 60 cells panels into 144 or 120 half-cut solar panels. The theory is almost similar, but each cell in 72 or 60 cells is cut into half to make them 144 or 120 half-cut cells respectively to make sure that they weigh less, and the clamp can be fitted whilst the cells are located on it without creating any marginal error. Apparently, each cell should have less current, but the robust wiring of the two half-cut cells in the panels makes it more efficient than the conventional solar cells and thus creates an equal current with half the resistance.

There are 4 sub-categories of Jinko Solar and they are;

- Eagle Series

- Swan Series

- Cheetah Series

- Tiger Series

Eagle series

Eagle series is the most basic series of Jinko which is polycrystalline and is always affordable for the low-income householders. They barely provide high efficiency along with the presence of little degradation. Swan Series used to be the most-used solar panels before Cheetah popped in as the series possesses bifacial qualities. Bifacial technology uses the reflected light through the rear side of the panel along with the front side. Therefore, it increases efficiency by 30%. However, both of these series got daggy as soon as the Cheetah and Tiger series ascended in the solar businesses. Cyanergy, welcomes all the customers with their vast collections of all of the 4 types of solar panels from the Jinko Solar manufacturer.

Cheetah Series

Cheetah is the most used solar panels among all the series of Jinko Solar owing to its good value for money, as well as, its outstanding quality. Having released in 2018 for the first time, it took the solar panel industry by storm by using the monocrystalline technology merged with Passivated Emitter and Rear Contact aka PERC solar cells. PERC cells are the modified version of the conventional solar cells, which can increase the energy by 6 to 12% since it uses an extra layer at the rear side of the solar panel to utilizes the rays that would otherwise get reflected away from the panels.

Cheetah offers both Half-cut (120 cells), as well as standard solar panels (60 cells). This series solar panels mostly come out with 60 and 72 cells, but recently they managed to squeeze another row of cells in the existing solar panels to make it either 66 or 78 cells. The power of the Cheetah series ranges from 315W to maximum of 445W, whereas efficiency varies from 18.88% to 20.50%. However, JKM330M-60H has become the top-selling solar panel in the entire Cheetah series in 2020. A 12 years product warranty along with 25 years performance warranty is a boon for the Jinko Cheetah series. However, one downside of the PERC solar cells in the Cheetah series is that they connect the panel with metal strips or ribbons. If they seal off or undergo shading, then the entire system will malfunction.

Tiger Series

As promised, Jinko Solar has recently launched its flagship Tiger and Tiger Pro series which comprise of the high-end technology, such as tilling ribbon (TR), 9 thin wire multi busbars, and half-cut cells. Both half-cut and 9BB features have added a revolutionary dimension to the Tiger series solar panels, increasing the efficiency of over 10%. The new Tiger series are rated from 360W to a remarkable 470W with the maximum efficiency rate of 21.16%. In the conventional 5BB, flat ribbon busbars are used using a paving technology which leaves a heap of gaps on the solar panel despite wielding it perfectly.

On the contrary, in the TR method, the gaps are eliminated by overlapping the cells using a pressing method just like a shingled cell using the circular ribbon, designed by the Jinko R&D. Having pressed the cells, the 9 busbars are connected to increase the spontaneous reabsorption of the light waves. Therefore, it prevents this N-type tiger series solar panels from misfiring the power when exposed to shading and increases the efficiency, performance, and reliability.

The ground-breaking discovery of Tiger Pro having a power up to 580W by Jinko Solar is another up-to-the-minute innovation of the Tiger series that contain the bevy of similar features of Tiger series, including 21.4% efficiency. This pro series has a capacity up to 580W, which makes it the most powerful solar panel on the market. However, initially, Jinko is contemplating releasing 530W Tiger Pro followed by it will manufacture 580W as the demand increases. In addition to, you will be provided with 15-years product warranty along with 30-years performance warranty which will suffice your need.

We, Cyanergy, take immense pleasure to notify you that we have a collection of all the Tiger series, including the latest Tiger Pro version. For more information, do visit our website, and don’t forget to ask us in the comment section below.